TEHNOMAT, KRANJ, D.O.O.

TEHNOMAT (pronounced Technomat) is a family-owned company, established in 1991.

| |

The company is based in Kranj, Slovenia, in a new, 2.400 square meter site, where an improved working environment has provided conditions for expanded production and sales.

In 2009 Tehnomat took over the ski pole accessories program from Kunzmann company from Ingolstadt, Germany. |

The company has a serious commitment to create a healthy, safe and motivating working environment and is organized into three co-ordinated departments:

- Injection Moulding Unit - producing a variety of plastic products

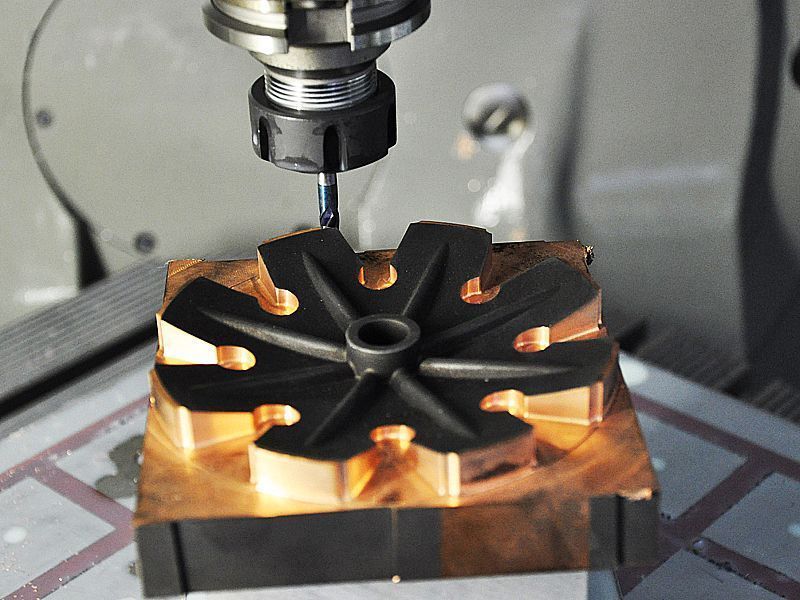

- The toolmaking Unit - designing and producing the actual moulds for each product

- The Tehnomat Brand Unit - producing of own line of final products

Environmental awareness of Tehnomat

We're well aware of the world's pollution as one of currently most exposed topics and a serious global problem.

For our plastic production we use certified and controlled "virgin" materials which comply EU directives that dictate product safety in the sense of human health and environment (REACH directive - restriction of chemicals; RoHS directive - restriction of the use of certain hazardous substances in electrical and electronic equipment).

The use of these virgin materials is the only option that gives us control over the quality of our products and for which we can guarantee 100%.

Therefore, to maintain a high quality of our products we don't use recycled materials, but we use the safest possible virgin raw materials.

Because the value of virgin raw materials is significant for us and also because of our environment protection mindset we recycle our own scrap material. There's no extra plastic waste as an outcome of our plastic production.

Our company Tehnomat is generally very environmentally friendly. We use energy-saving machines and lighting. The electricity that powers our machines is entirely solar - a part comes from our solar plant on the roof of the building and the rest is provided by electricity company offering power source options, where we again chose solar source.

We also "recycle" water - we built a water tank under our production hall which is a source of water used for cooling down the machines. In the cold days we use this machine-heated water for central heating.

We'll do our best to produce high quality materials also in the future and we're working on having the minimum possible impact on the environment and living creatures.

|

|

|